Innovative Ceramic Products for Foundries

In today’s market, many metal casters consider the use of ceramic gating components necessary for the production of quality castings and ICP is the leader in this industry. Our products for metal casting include ceramic strainer cores, runner tubes, fittings, pouring cups and many special gating pieces.

The use of ceramic gating components for steel castings is now a widely acknowledged method to improve castings and ICP continues to break new ground on quality of ceramics for this market.

Not only do these components withstand thermal shock and high temperatures, but recent innovations also include a spall resistant tube that has been used successfully in some of the largest castings poured.

ICP does not stop with good products. It is a committed belief that product and service are equal partners in any successful company and we pride ourselves on both. Our personnel are aware that our future depends on our customers and have been trained to be both knowledgeable and courteous.

We appreciate the trust our current customers place in us and would like to be given a chance to talk with any foundry on the advantages of using our gating components.

Ceramic Tubes

ICP Ceramic Tubes, manufactured from specially formulated ceramic bodies, are white and free of iron sulfide. Compositions are available for special applications and tubes can be manufactured from ICP mullite, fireclay or fused silica. Any fractional length or tubes longer than 12″(304mm) can be produced upon request. ICP tubes are non-eroding, and assure a smooth slag-free passage of metal to mold cavity without contamination or reaction with metal. Ends are precision-made for a sure fit. ICP Ceramic Tubes are available in a wide range of sizes: standard plain end, mitered and male-female ends. We also offer bent, curved, notched and reducer tubes. Samples are available on request.

Bent Tubes

ICP bent tubes are available in a variety of shapes and sizes, and in both mullite and fused silica composition.

Squashed Tubes

ICP squashed tubes are available in a variety of shapes and sizes, and in both mullite and fused silica compositions.

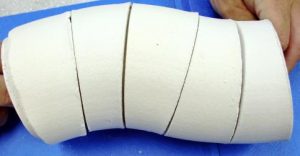

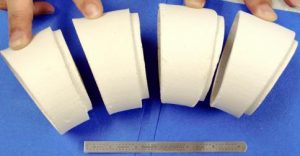

Segmented Tubes

ICP segmented tubes are designed to facilitate complex gating of castings. Oftentimes foundries cut and grind standard runner tubes into shorter lengths and then re-assemble to form a non-linear runner. ICP segmented tubes can be made with male/female ends and easily assembled to create a variety of non-standard geometries such as S curves.

Ceramic Ladle Tiles

ICP ladle tiles are available in a variety of shapes and sizes, and in both mullite and fused silica composition.

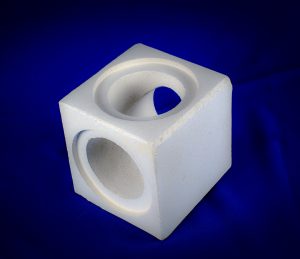

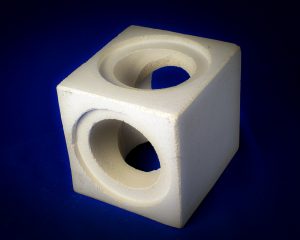

Ceramic Fittings

ICP ceramic fittings are single-piece units of the highest quality designed for erosion and spall resistance. These fittings are available in the standard elbow, tee, and cross geometries, as well as many custom configurations. Combinations of inlet and outlet diameters in a single-unit are available upon request.

F-Style Ceramic Pour Cups

F – Style pour cups are designed to be used with standard ICP gating components and are made with outlet recesses to fit ICP runner tubes or reducers. Normally positioned so that the cup inlet is level with the top of the flask, ICP pour cups minimize defects caused by sand and re-oxidation inclusions. These cups can be produced from mullite or fused silica materials.

Zero Vortex (OV) Pour Cups

A concern for quality minded metal casters is re-oxidation inclusions caused by the entrapment of air during the casting process. A concentric pouring basin can cause a vortex effect which sucks excess air into the mold during the pour. The resulting defects may need to be welded or repaired before the casting becomes acceptable to the customer.

ICP has developed the OV pour cup for these applications. By incorporating a flat-sided inlet design, the OV pour cup minimizes the vortex effect. All ICP F-Style pour cups can be made with this flat sided design while maintaining a round outlet designed to mate with ICP tubes.

An additional advantage of the ICP OV pour cups is that the anti-swirl effect causes a faster feed rate. The quicker feed rate allows the use of a smaller size pour cup, since excess fill height is not needed to maintain adequate feed rate.

Duck Feet

ICP Duck Feet are used as casting ingates, designed to reduce erosion on the surfaces of cores and molds by allowing the metal to calmly feed into the mold, thereby reducing turbulence. Easy removal of these ingates continues to be another benefit (knock off). The casting finish is better at the ingates due to the sharp clean edges of the ICP Duck Feet. Other benefits include:

- Erosion reduction

- Better casting finish

- Fewer Inclusions

- Less gate grinding

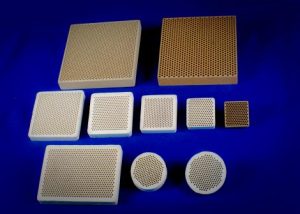

Ceramic Filters

Ceramic filters are used to remove impurities from metals, and in today’s market, many metal casters consider the use of ceramic filters necessary for the production of quality castings. Because ceramic filters can withstand extremely high temperatures, their use in foundry and investment casting processes continues to be essential. ICP is the leader in this industry, and our ceramic filters for metal casting come in a variety of shapes and sizes.

Ceramic Strainer Cores

ICP strainer cores are manufactured from high grade mullite material and can be used for steel, gray, and ductile iron.

Advantages

- Cost effective

- Flow control

- High strength

- Mullite material

- Stable dimensions

- Many sizes

- O. D. draft

- No outgassing

- Slag reduction

- Quick delivery

- Consistent quality

- Stops vortexing

- Better castings

Breaker Cores

ICP breaker cores are designed to be a cost effective alternative to sand cores while providing some additional benefits. Ceramic breaker cores are sintered mullite and contain no volatile combustibles. The thermal conductivity properties of the ceramic prevent heat loss which can cause premature cooling of the metal at the juncture. High mechanical strength and smooth, hard surfaces facilitate separation of the riser from the casting. Labor savings are realized due to easy riser removal.

Molten Metal Samplers

ICP offers a selection of fused silica based products for molten metal sampling including test coupons, assay cups, crucibles, and sampling rings. Also available are samplers designed for use with standard spectrographic analysis equipment. ICP molten metal samplers allow quick, convenient, inclusion free sampling.